Our elastomers are the next generation of standard materials that can replace vulcanized rubber and other materials.

Our elastomers are highly functional products produced by our advanced compounding and blending technologies that can meet all kinds of customer needs, and are used in an extremely wide range of fields, including food, medical, general merchandise, daily necessities, home appliances, automotive-related products, and toys.

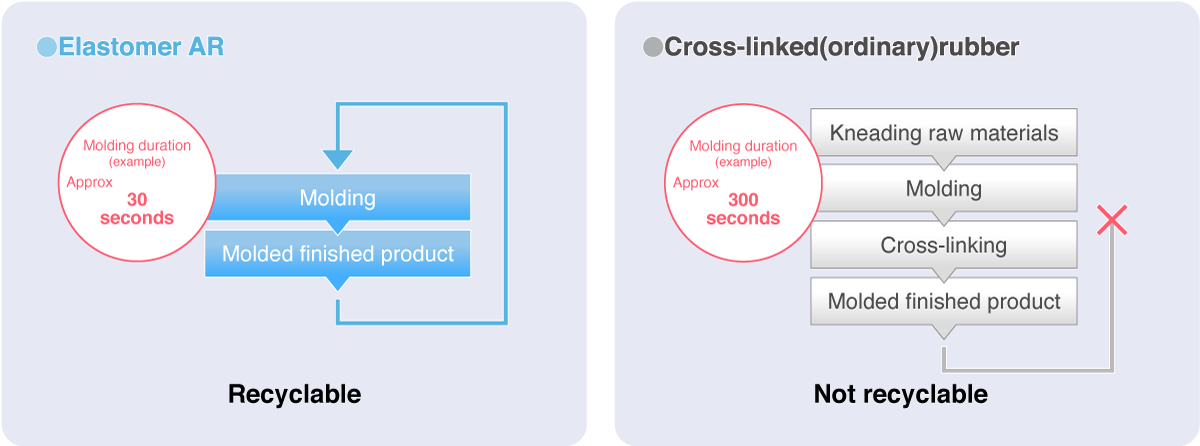

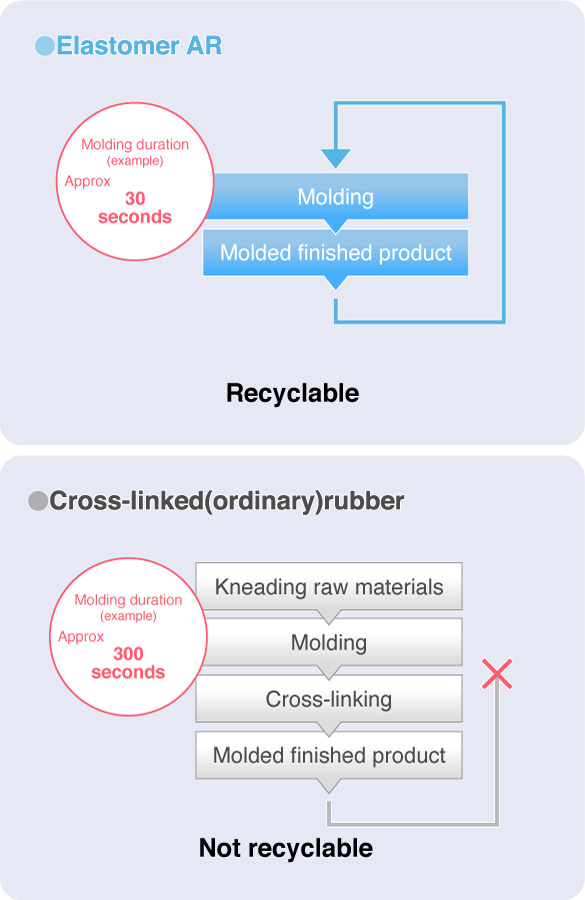

Thermoplastic elastomers are materials that have elasticity close to that of rubber, yet can be molded with the same ease

as general-purpose plastics.Since they can be selected from a large number of series according to the application and the

molding process can be shortened, they are highly anticipated as an alternative to cross-linked rubbers.It is also recyclable,

making it a next-generation molding material that is attracting attention not only for its cost advantage but also from the

perspective of environmental preservation.

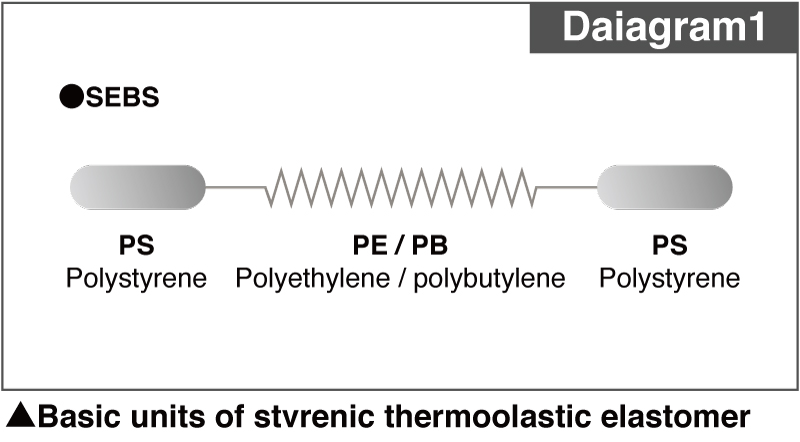

Styrene thermoplastic elastomers have a base unit structure that polystyrene components (hard segments) and polyethylene-polybutylene components (soft segments) are copolymerized in a block shape (Diagram 1).

These are represented as SEBS.

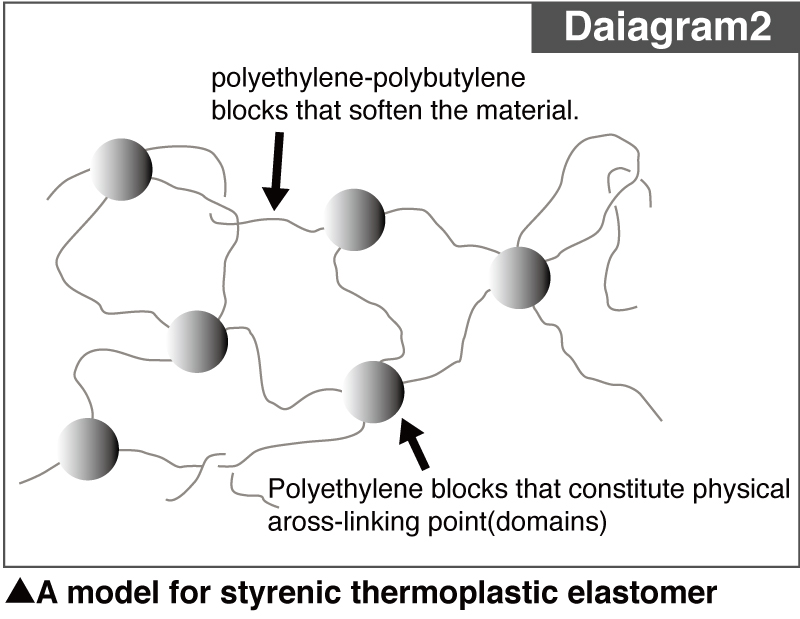

An end block of polystyrene and a middle block of polyethylene-polybutylene are chemically compounded; however, they are not thermodynamically compatible at room temperature.

For the reason, the end blocks of polystyrene are mutually agglutinated and form ultrafine microparticles (domain) and dispersed uniformly (Diagram 2).

This polystyrene domain becomes a physical cross-linking point and plays a role equivalent to the cross-linking point of cross-linked rubber, so SEBS show characteristics as an elastic body.

However, polystyrene components and polybutadiene or polyethylene-polybutylene components are melted together at a temperature of140℃ to 230℃ that allow injection or extrusion molding.

This shows the flow characteristics as thermoplastic resin.

"Elastomer AR" and "Arostomer" are based on SEBS and have various functions such as hygiene, transparency, and vibration damping.

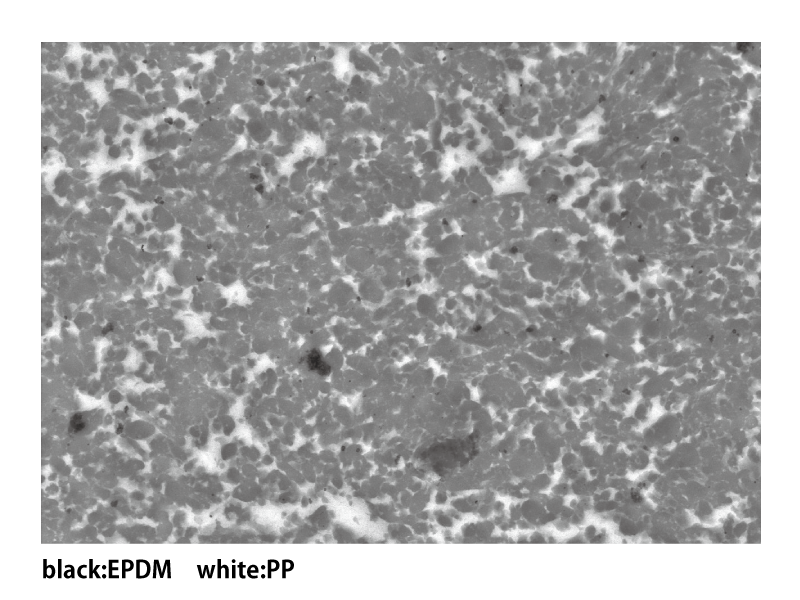

ARVAS is a dynamic cross-linking type olefin thermoplastic elastomer (TPV: Thermoplastic Vulcanizates Elastomer) in which polyolefins such as PP and PE are used as hard segments and the rubber component of Ethylene Propylene Diene Monomer(EPDM) is used as soft segments.

A partially cross-linked type (VP series) with low specific gravity,excellent moldability and colorability is available.

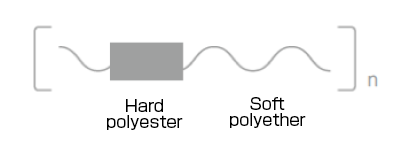

Polyester thermoplastic elastomers are copolymers of aromatic polyester hard segments and aliphatic polyether soft segments.

This polymer intertwines like cotton fibers, giving it rubber elasticity and strength.

Based on this polymer, "ESTERAR" is developed as a series with various functions such as conductivity, abrasion resistance, and heat resistance.

Heat |

Weather |

Water |

Acid resistance/ |

Oil |

Hygiene |

Transitivity |

Transparency |

Printability/ |

||

|---|---|---|---|---|---|---|---|---|---|---|

High |

TPS | ○ | ◎ | ◎ | ◎ | △ | ◎ | ○ | ○ | △ |

| TPV | ○ | ◎ | ◎ | ◎ | △ | × | ○ | × | △ | |

| TPU | △ | × | × | △ | ◎ | ◎ | ◎ | ◎ | ◎ | |

| TPC | ◎ | △ | △ | △ | ◎ | △ | ◎ | × | ◎ |

◎:Very excellent

○ : Exellent or usable under ordinary conditions

△ : Relatively poor or conditionally usable

× : Poor or almost unusable

| Thermoplastic elastomer (TPE) | Vulcanized rubber | |

|---|---|---|

| Weight | ○:Low specific gravity (0.9) possible | ×: High specific gravity |

| Hygiene | ○: No vulcanizing agent used, low risk of elution | ×: Concern about elution of vulcanizing agent |

| Environmental impact | ○:Recyclable | ×: Not recyclable |

| Colorability | ○: Can be easily colored in a variety of colors | ×: There are many black and white components, and there is little freedom in color. |

| Formability・ Molding equipment |

○: Molding cycle is short and can be molded with general-purpose molding machines | ×: Molding cycle is long due to vulcanization process |

| Long term performance | ×: Low durability in harsh environments due to uncrosslinked | ○: Excellent durability under harsh environments due to crosslinking. |

| Oil resistance | ×: Due to its molecular structure, it is easily affected by oil. | ○: High resistance to various types of oil (depending on the rubber type) |

| Heat-resistance (150℃ or more) |

×: Difficult to maintain shape due to thermoplasticity | ○: Due to crosslinking, it is less affected by heat and performance deterioration is small. |