| time | unit | AROSTOMER | Elastomer AR | ARVAS | ESTERAR | |||

|---|---|---|---|---|---|---|---|---|

| TF-A60NT-N1 | T-A60NT-N1 | AR-BOIX-60N | VP-A60NT-N1 | ES-A60NX | ||||

| test temperature | ℃ | 100℃ | 100℃ | 100℃ | 100℃ | 120℃ | 120℃ | |

| 500hr | Tensile strength retention | % | 121 | 143 | 138 | 108 | 104 | 72 |

| Elongation retention | % | 95 | 78 | 121 | 74 | 90 | 84 | |

| Hardness change | point | + 4 | - 1 | -1 | + 2 | ±0 | -3 | |

| 1000hr | Tensile strength retention | % | 130 | 148 | 118 | 93 | 112 | 35 |

| Elongation retention | % | 70 | 70 | 81 | 93 | 80 | 54 | |

| Hardness change | point | + 5 | ±0 | - 3 | + 1 | + 3 | -11 | |

Appearance evaluation: ○: Not changed, △: Slightly colored, ▲: Colored, ●: Swelled or shrinkaged

Test condition : AROSTOMER 23℃×240hr、ARVAS 23℃×240hr、ESTERAR 23℃×168hr

| Chemicals | AROSTOMER | ARVAS | ESTERAR | ||||||

|---|---|---|---|---|---|---|---|---|---|

| TF-A60NT-N1 | VP-A60NT-N1 | ES-A70NX | E-D42N | ||||||

| weight change(%) | appearance | weight change(%) | appearance | weight change(%) | appearance | weight change(%) | appearance | ||

| Sulfuric acid | 3% | - | - | - | - | + 0.1 | ○ | + 0.1 | ○ |

| 30% | -0.06 | △ | + 0.06 | ○ | + 0.2 | ○ | + 0.2 | ○ | |

| 98% | -0.06 | △ | + 4.01 | ▲ | + 68.5 | ● | dissolution | - | |

| Nitric acid | 10% | + 1.02 | ▲ | + 0.36 | △ | + 1.3 | △ | + 1.3 | △ |

| 60% | + 10.8 | ▲ | + 9.70 | ▲ | + 58.0 | ● | dissolution | ● | |

| Hydrochloric acid | 10% | + 0.34 | ▲ | + 0.06 | ○ | - | - | - | - |

| 36% | + 8.11 | ▲ | + 1.35 | ▲ | - 0.9 | △ | dissolution | ● | |

| Acetic acid | 10% | - | - | + 1.51 | △ | + 1.3 | △ | + 1.5 | △ |

| 100% | - | - | -2.88 | ▲ | + 24.0 | ▲ | + 12.5 | ▲ | |

| Sodium hydroxide | 10% | - 0.03 | ▲ | + 0.20 | △ | - | - | - | - |

| 40% | + 0.03 | ▲ | + 0.25 | ▲ | - 0.2 | ○ | - 0.3 | ○ | |

| Sodium chloride | 10% | - 0.01 | ○ | -0.17 | ○ | + 0.2 | ○ | + 0.2 | ○ |

| Salad oil | - 3.63 | ○ | -13.0 | ○ | + 6.3 | △ | + 1.1 | △ | |

| Chlorinated bleach | + 0.04 | ○ | + 0.01 | ▲ | + 0.1 | ○ | + 0.1 | ○ | |

| Neutral detergent | - 2.15 | ○ | -4.24 | ○ | + 0.9 | ○ | + 2.0 | △ | |

| Hair tonic | + 1.17 | ○ | + 1.37 | △ | + 2.5 | △ | + 2.5 | △ | |

| Ethanol | 10% | - | - | - | - | - | - | - | - |

| 50% | + 0.41 | ○ | + 0.03 | ○ | + 1.0 | ○ | + 1.4 | △ | |

| 100% | - 11.7 | ○ | -11.6 | △ | - 4.7 | △ | + 1.2 | △ | |

| Methanol | 10% | - | - | - | - | ±0.0 | ○ | + 0.2 | ○ |

| 50% | + 0.24 | ○ | ±0.00 | ○ | + 0.1 | ○ | + 0.4 | ○ | |

| 100% | - 0.56 | ○ | -4.07 | △ | - 1.2 | ○ | - 0.1 | ○ | |

| IPA | - 19.6 | ● | -24.5 | △ | - 5.2 | △ | + 2.7 | △ | |

| Ehylene glycol | + 0.03 | ○ | -0.08 | ○ | + 0.5 | ○ | + 0.8 | ○ | |

| Toluene | + 24.5 | ● | + 102 | ● | - 18.5 | ▲ | + 1.9 | △ | |

| Xylene | + 26.6 | ● | + 127 | ● | - 15.7 | ▲ | + 4.0 | △ | |

| Carbon tetrachloride | - | - | - | - | - 8.8 | △ | + 12.5 | △ | |

| Gasoline | + 10.3 | ● | + 128 | ● | + 76.1 | ● | + 20.1 | ● | |

| Kerosene | + 130 | ● | + 134 | ● | + 50.1 | ● | + 9.8 | △ | |

| ASTM No.1oil | + 9.06 | ▲ | + 12.6 | △ | + 2.3 | △ | + 0.2 | ○ | |

| IRM903oil | + 67.6 | ● | + 110 | ● | + 38.6 | ▲ | + 5.5 | △ | |

| Silicon grease | - 5.92 | ○ | -7.02 | ○ | - | - | - | - | |

test machine:Sunshine Weather Meter

test condition:temperature 63℃、rain cycle 12min/1hr

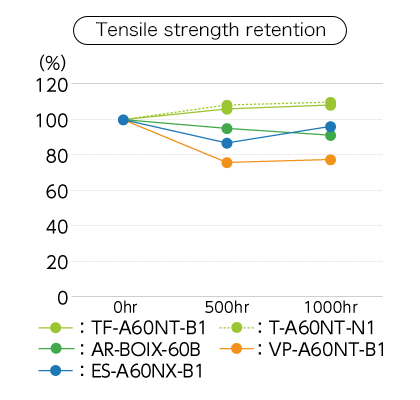

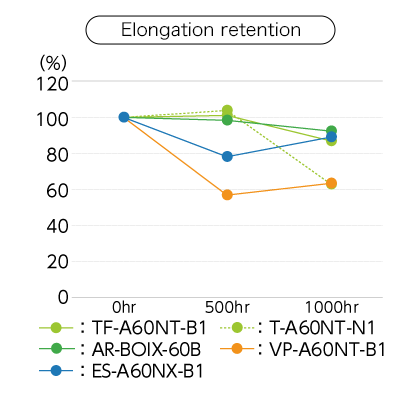

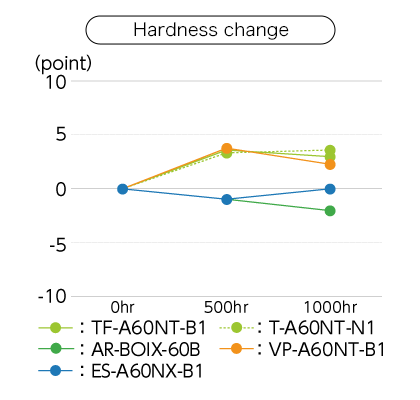

| time | unit | AROSTOMER | Elastomer AR | ARVAS | ESTERAR | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| TF-A60NT-N1 | TF-A60NT-B1 | T-A60NT-N1 | AR-BOIX-60B | VP-A60NT-N1 | VP-A60NT-B1 | ES-A60NX | ES-A60NX-B1 | |||

| 500hr | Tensile strength retention | % | 101 | 106 | 108 | 95 | 92 | 76 | 56 | 87 |

| Elongation retention | % | 96 | 101 | 104 | 98 | 38 | 57 | 77 | 78 | |

| Hardness change | point | + 5 | + 4 | + 8 | - 1 | + 3 | + 4 | - 4 | - 1 | |

| 1000hr | Tensile strength retention | % | 110 | 108 | 110 | 91 | 95 | 77 | 44 | 96 |

| Elongation retention | % | 63 | 87 | 63 | 92 | 39 | 63 | 63 | 89 | |

| Hardness change | point | + 4 | + 3 | + 4 | - 2 | + 1 | + 2 | - 6 | ±0 | |

*Click on the series name to jump to the introduction page for each series. *

| Our products | base material | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| PP | ABS | PC | PET | PET-G | 6Ny(PA) | PBT | POM | AS | |||

| AROSTOMER | TF series | ○ | × | × | × | - | × | × | × | - | |

| T series | |||||||||||

| Elastomer AR | AR-800 series | ||||||||||

| AR-1000 series | |||||||||||

| AR-2000 series | |||||||||||

| AR-SC series | |||||||||||

| AR-DM series | |||||||||||

| AR-GB series | |||||||||||

| AR-NK series | |||||||||||

| AR-BO series |

AR-BOIX | × | ○ | ○ | ○ | ◎~○ | ◎~× | × | × | ◎ | |

| AR-BOIC-50 | |||||||||||

| AR-BOIN | × | ○ | ○ | ○ | ◎ | ○ | - | × | - | ||

| AR-BOIC-70 | × | ○ | ○ | ○ | △ | - | × | × | - | ||

| AR-BOEX | |||||||||||

| AR-BOI-HY70 | × | ○ | ○ | ○ | - | ○ | - | × | ○ | ||

| AR-BOIA-60 | × | ○ | ○ | ○ | - | - | △ | ○※ | - | ||

| ARVAS | VP series | ○ | × | × | × | - | × | × | × | - | |

| ESTERAR | E series |

E-D27N | × | △ | ◎ | - | ◎ | - | × | - | - |

| E-D42N | |||||||||||

| E-D45CD | |||||||||||

| E-D53N | × | × | ○ | - | △ | - | × | - | - | ||

| ES series |

ES-A50NX | × | ○ | ○ | - | ○ | - | × | × | ○ | |

| ES-A60NX | × | ○ | ◎ | - | ○ | - | × | × | ○ | ||

| ES-A70NX | |||||||||||

| ES-A80NX | |||||||||||

| ES-A75PB | × | ○ | ◎ | - | ○ | × | ○※ | ○※ | ○ | ||

| C series | × | ○ | ○ | - | ○ | - | - | - | - | ||

| S series |

ES-A50S1 | × | ○ | ○ | - | - | - | - | - | - | |

| ES-A70S1 | |||||||||||

| E-D27S1 | × | △ | ○ | - | - | - | - | - | - | ||

| E-D53S1 | × | × | ○ | - | - | - | - | - | - | ||

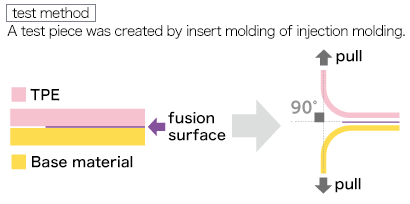

◎:powerful fusion(Impossible to peel off by human force)

○:fusion(Difficult to peel off by human power, considerable force is required)

△:weak fusion(Can be peeled off by pulling strongly)

×:do not fuse(Easy to peel off with weak force)

- :No data

※By heating the base material to be fused, we recommend molding in a state where the fusion strength is improved.

| AROSTOMER | Elastomer AR | ARVAS | ESTERAR | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TF series T series |

AR-800 series AR-2000 series AR-NK series |

AR-1000 series AR-DM series |

AR-SC series |

AR-FL series※ |

AR-GB series |

AR-BO series |

AR-NF series |

AR-EL series |

VP series |

E series |

ES series C series S series |

EA series |

||

| Injection | Underneeth the hopper(℃) | 50 | 50 | 50 | 50 | - | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Cylinder(℃) | 140~200 | 140~200 | 140~220 | 120~200 | - | 140~220 | 140~220 | 140~190 | 140~220 | 160~200 | 160~230 | 150~220 | 180~240 | |

| Nozzle(℃) | 180~220 | 180~220 | 200~240 | 160~220 | - | 200~240 | 200~260 | 170~190 | 200~240 | 200~220 | 170~240 | 170~230 | 220~250 | |

| Mold(℃) | 30~50 | 30~50 | 30~50 | 30~50 | - | 20~60 | 30~50 | 30~50 | 30~50 | 30~50 | 20~40 | 20~40 | 40~60 | |

| Cooling Time(Sec) | 10~20 | 10~20 | 10~20 | 10~20 | - | 10~30 | 10~30 | 10~20 | 10~20 | 10~20 | 10~40 | 10~40 | 10~30 | |

| Extrusion | Cylinder(℃) | 140~200 | 140~200 | 140~200 | 120~190 | 140~200 | 140~200 | 140~220 | 140~180 | 140~200 | 150~200 | 160~230 | 150~200 | 170~230 |

| Die(℃) | 160~200 | 160~200 | 180~220 | 160~200 | 180~220 | 180~220 | 180~240 | 160~180 | 180~220 | 180~210 | 170~230 | 160~210 | 200~240 | |

| Drying | ー | 80~90℃×3~4hr | ー | 80~90℃×3~4hr | ||||||||||

The above conditions are for reference only.

※The extrusion molding temperature for ”AR-FL series” is the set temperature for film molding.

The gate shown in Figure A may fail due to jetting. B- or C-type gate is recommended.

●Designing a mold can be essentially the as same as that of olefin resins. It may not be well released only by extrusion pins for its soft material and product shape. In this case, we recommend using a combination of air and a stripper plate.

●For gas release, secure 1/100 mm to 2/100 mm.

●Flow marks may be caused, so we recommend a stain finish or a grain finish for the product surface.

- Each of the characteristic values in the data are typical measurement values, not guaranteed values.

- When considering use to members which contact oil, you must contact our sales representatives in advance to inquire of the use environment and conditions. Deformations or color modifications may occur to the molding items depending on the use environment and conditions.

- When considering use to members which are related to physical bodies such as medical and food use, you must contact our sales representatives in advance.We will not be liable for any accidents caused by use to the members related to your body such as members for medical use and for foods without our consent.

- For the use of our elastomers, please test and confirm safety, conformity, and intellectual property issues in advance.